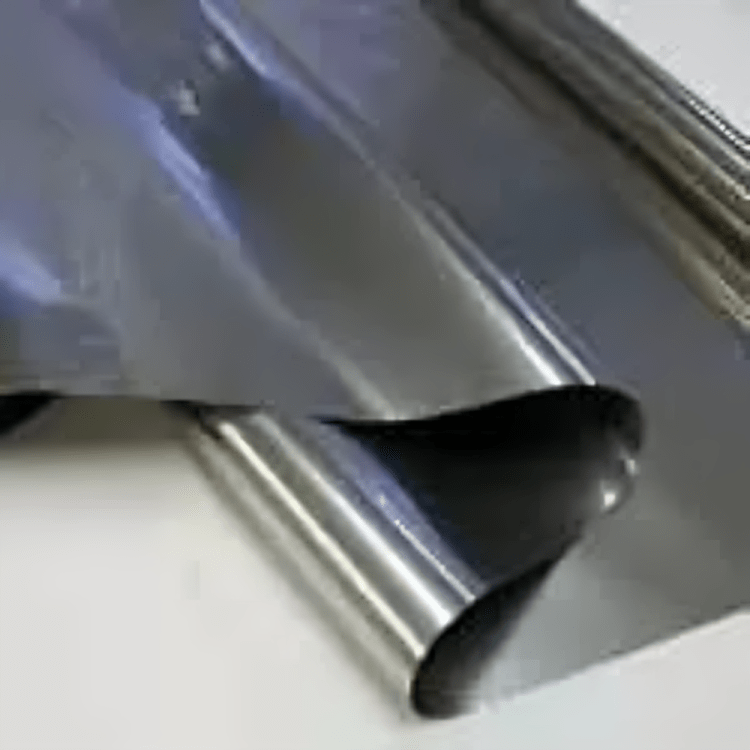

Inconel 600 Sheet / Plate / Coil

Established in 2005, Siddhgiri Tubes has earned a stellar reputation as a leading manufacturer of Inconel 600 Sheet / Plate / Coil, With nearly two decades of expertise, the company is renowned for delivering high-quality products that cater to diverse industries, including construction, automotive, manufacturing, and more.

Siddhgiri Tubes prides itself on its commitment to excellence, utilizing advanced manufacturing techniques and state-of-the-art technology to produce durable and precision-engineered SS products. Their product range is available in various grades, finishes, and dimensions, ensuring versatility and meeting the precise needs of their clients.

The company’s foundation is built on strong principles of customer satisfaction, innovation, and reliability. Siddhgiri Tubes adheres to stringent quality standards and employs a team of skilled professionals dedicated to maintaining the highest levels of production efficiency and product consistency.

Inconel 600 Sheet, Plate & Coil Specifications

| Specifications | : | ASTM / ASME SB 168 /AMS 5540 |

| Size | : | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | : | 0.1mm to 50 mm Thk |

| Form | : | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Finish | : | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | : | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Types of Inconel 600 Sheets, Plates & Coils

- Alloy 600 Foils

- 600 Inconel Foils

- 600 Alloy Foils

- Inconel UNS N06600 Foils

- Inconel WERKSTOFF NR. 2.4816 Foils

- ASME SB168 Inconel Foils

- Alloy 600 Shim Sheet

- 600 Inconel Shim Sheet

- Inconel UNS N06600 Shim Sheet

- 600 Alloy Shim Sheet

- Inconel WERKSTOFF NR. 2.4816 Shim Sheet

- ASTM / ASME SB168 Inconel Shim Sheet

- Alloy 600 Polished Plates

- 600 Inconel Polished Plates

- 600 Alloy Polished Plates

- Inconel UNS N06600 Polished Plates

- Inconel WERKSTOFF NR. 2.4816 Polished Plates

- ASTM / ASME SB168 Inconel Polished Plates

- Alloy 600 Hot Rolled Plates

- 600 Inconel Hot Rolled Plates

- 600 Alloy Hot Rolled Plates

- Inconel UNS N06600 Hot Rolled Plates

- Inconel WERKSTOFF NR. 2.4816 Hot Rolled Plates

- ASME SB168 Alloy Hot Rolled Plates

- Alloy 600 Cold Rolled Plates

- 600 Inconel Cold Rolled Plates

- 600 Alloy Cold Rolled Plates

- Inconel UNS N06600 Cold Rolled Plates

- Inconel WERKSTOFF NR. 2.4816 Cold Rolled Plates

- ASTM / ASME SB168 Inconel Cold Rolled Plates

- Alloy 600 Coils

- 600 Inconel Coils

- 600 Alloy Coils

- Inconel UNS N06600 Coils

- Inconel WERKSTOFF NR. 2.4816 Coils

- ASTM / ASME SB168 Inconel Coils

- Alloy 600 Strips

- 600 Inconel Strips

- 600 Alloy Strips

- Inconel UNS N06600 Strips

- Inconel WERKSTOFF NR. 2.4816 Strips

- ASME SB168 Inconel Strips

- Alloy 600 Circle

- 600 Inconel Circle

- 600 Alloy Circle

- Inconel UNS N06600 Circle

- Inconel WERKSTOFF NR. 2.4816 Circle

- ASME SB168 Inconel Circle

Inconel 600 Plate, Sheet & Coil Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Alloy 600 Sheets, Plates & Coils Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

Equivalent Grades for 600 Inconel Sheets & Plates

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Inconel 600 Sheets, Plate & Coils Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

ASTM / ASME SB 168 Inconel 600 Sheets, Plate & Coils Value Added Services

Material Testing:

We at Siddhgiri Tubes ensure that all our materials go through strict quality tests before dispatching them to our clients.

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Chemical Analysis – Spectro Analysis

• Positive Material Identification – PMI Testing

• Flattening Test

• Micro and MacroTest

• Pitting Resistance Test

• Flaring Test

• Intergranular Corrosion (IGC) Test

Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

• Form A for the purposes of the Generalized System of Preferences (GSP)

Categories

Inconel Sheet /Plate /Coil

Monel Sheet/Plate/Coil

Titanium Sheet / Plate / Coil

Hastelloy Sheet / Plate / Coil

Nickel Sheet / Plate / Coil

Brass Sheet / Plate / Coil

Copper Sheet / Plate / Coil

Aluminium Sheet / Plate / Coil

AISI 4130 Sheet / Plate / Coil

SMO 254 Sheet / Plate / Coil

Alloy 20 Plate